Rapid Delivery for Luggage Net - Biodegradable Biomass & compostable Polylactic acid (PLA) Yarn Fiber Natural Corn Fiber Staple Short Cut Fiber – AOPOLY

Rapid Delivery for Luggage Net - Biodegradable Biomass & compostable Polylactic acid (PLA) Yarn Fiber Natural Corn Fiber Staple Short Cut Fiber – AOPOLY Detail:

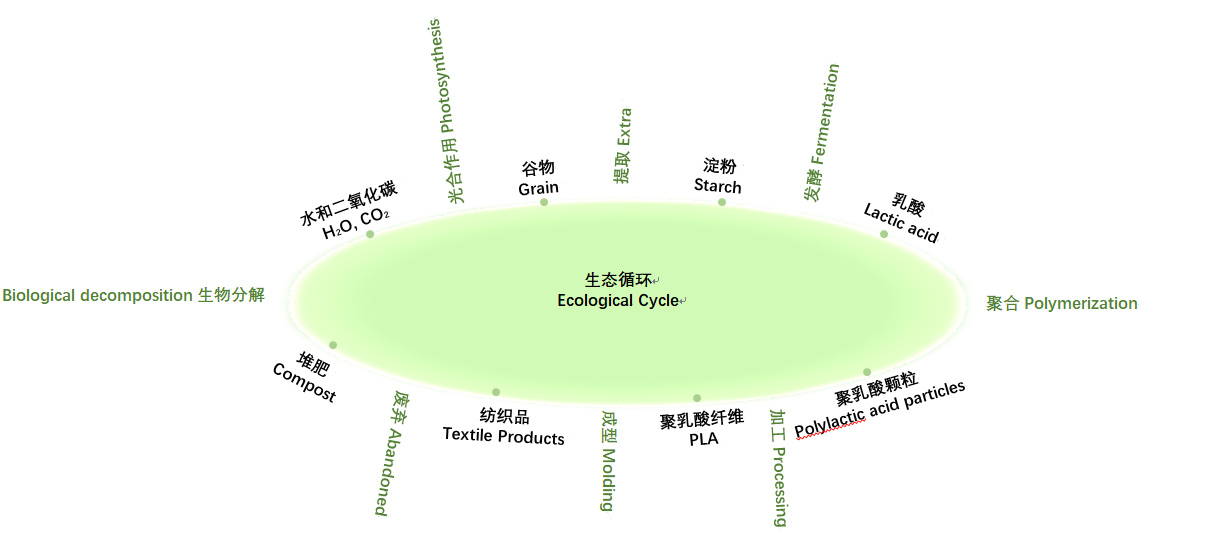

Polylactic acid fiber (PLA) also known as polylactide fiber is a new type of biodegradable biomass fiber that uses renewable plant resources (such as corn, wheat, and tapioca starch) as raw materials to obtain glucose through saccharification. Certain strains are fermented to produce high-purity lactic acid, and polylactic acid with a certain molecular weight is synthesized through chemical synthesis methods, then polymerized and spun to make new fibers which are common natural substances in organisms (including human bodies). PLA fiber has good biocompatibility and bioabsorbability as well as good biodegradability, bacteriostasis, flame retardancy, warmth retention, moisture absorption and breathability. Polylactic acid fiber (PLA) is made from starch with lactic acid as raw material and the production process is pollution-free. The solid waste after use can be completely degraded into carbon dioxide and water by microorganisms in soil and water, and will not pollute the environment. Under sunlight and photosynthesis, plants can regenerate carbon dioxide and water in the air into starch which can be recycled in nature. This is very beneficial to protecting the environment and is recognized as a green polymer and environmentally friendly material.

Antibacterial mechanism: The low-polymerization fatty acid chain in PLA fiber can destroy harmful cell walls/membrane. The acidic substance released by the low-polymerization fatty acid chain destroys the acid-base balance in the cell body, causing the leakage of intracellular substances, which causes a A series of chain reactions eventually destroy the living environment of harmful bacteria, leading to the death of harmful bacteria.

Main Properties

◎ Environmental protection: PLA products buried in soil or water will decompose into CO2 and H2O

◎ Good processing performance: similar strength and elongation with polyester and nylon, while lowest melting point and low modulus

◎ Soft and smooth: with silk-like soft luster and touch, good drape, currently closest to mulberry silk

◎ Good biocompatibility: derived from natural plants, weakly acidic

◎ Natural skin-friendly: especially suitable for allergic constitution, pregnant women, infants and special groups

◎ Insulation close-fitting: good resilience, high fluffiness, warmth is 1.8 times higher than high-quality cotton core

◎ Bacteriostatic and anti-mite: textiles will automatically sort out 17 small molecules such as lactic acid during use, forcing mites to escape, and the bacteriostatic rate of bacteria and fungi is greater than 98%, which has excellent anti-mite and anti-mite effects.

◎ Breathable & moisture removal: unique fiber microstructure brings excellent breathable and moisture conductivity

◎ Excellent flame-retardant effect, good heat resistance and UV resistance

Main Applications

Clothes, Bedding, Hygiene products, Underwear, Maternal and baby products, Socks.

Parameters

Garment performance comparison between PLA fiber and other fibers

| Fiber type | Polyester | Cotton | Silk | Bamboo Fiber | PLA |

| acteria & mite resistance |

Poor | Poor | Fair | Good | Excellent |

| Breathability | Poor | Fair | Poor | Good | Excellent |

| Fire resistance | 20 | 16 | 17 | 18 | 26~30 |

| PH Value | - | - | 7 | - | 6~6.3 |

| Degradability | Very Poor | Good | Good | Good | Excellent |

| Drapability | Fair | Poor | Good | Poor | Excellent |

| Wrinkle resistance | Good | Fair | Poor | Fair | Excellent |

| Heat retention | Fair | Good | Poor | Good | Good |

| Cooling performance | Fair | Good | Poor | Good | Excellent |

| Raw material | Petrol | Cotton | Silk | Bamboo | Lactic acid |

| Pollution | Chemical pollution | Pesticide residue | None | Chemical extraction | None |

Processing performance comparison between PLA fiber and other fibers

| Fiber type | Cotton | Viscose | Silk | Wool | PLA | Nylon | Polyester | Acrylic |

| Relative density | 1.52 | 1.52 | 1.3-1.45 | 1.32 | 1.27 | 1.14 | 1.38 | 1.8 |

| Strength (g/d) | 1.9-3.1 | 2.5 | 4 | 1.6 | 3.8-4.5 | 4.5 | 4-4.5 | 4 |

| Stretch (5%) | 52 | 32 | 52 | 69 | 93 | 89 | 65 | 50 |

| Melting point(℃) | - | - | - | - | 60-175 | 215 | 255 | 320 |

| Flammability | Burning | Burning | Burning | Burning(slow) | Less smoke (extinguish after 2” without fire) | Medi-smoke | Much smoke (extinguish after 6” without fire) | Medi-smoke |

| Heat of combustion (MJ/KG) | 17 | 17 | - | 21 | 19 | 31 | 25-30 | 31 |

| Oxygen Limitation index (%) | 16-17 | 17-19 | - | 24-25 | 28 | 20-24 | 20-22 | 18 |

| UV resistance | Fair Poor | Poor | Fair Poor | Fair | Excellent | Poor | Fair | Excellent |

| Gloss angle | 1.53 | 1.52 | 1.54 | 1.54 | 1.35-1.45 | 1.52 | 1.54 | 1.5 |

| Water contact angle | - | - | - | - | 76 | 70 | 82 | - |

| Spinning method | - | Wet spinning | - | - | Melting spinning | Melting spinning | Melting spinning | Dry spinning |

Specification

| Fiber type |

Size |

Properties |

Applications |

| PLA FDY & PLA DTY |

FDY: Linear: 75D~300D / 36F~96F DTY: Linear: 50D~200D / 24F~72F |

◎ Antibacterial naturally ◎ Renewable & sustainable ◎ 100% Biodegradable & compostable ◎ Low carbon and friendly with environment |

Apparel, Textile |

| PLA Microfiber |

Linear: 0.5D~0.9D Length: 5mm / 6mm / 12mm / 18mm / 38mm / 51mm / 64mm ~102mm Type: Crimp / Uncrimp |

◎ Soft feel ◎ Excellent moisture bsorbency |

Nonwoven, Paper-making, Oil exploration, Apparel, Textile |

| PLA Fiber for Spinning | Linear: 0.5D / 0.6D / 0.8D / 0.9D / 1.2D / 1.3D / 1.5D / 2D / 3DLength: 36mm / 38mm / 51mm | ◎ Odor resistance◎ Light and lofty feel

◎ Excellent skin affinity ◎ Good moisture transport ◎ Excellent shape retention and crease resistance |

Pure or blending spinning for apparel and textile |

| PLA Staple Fiber | Linear: 0.8D / 0.9D / 1.2D / 1.3D / 1.5D / 2D / 3DLength: 5mm / 6mm / 12mm / 18mm

Dry or Moisture 15% |

◎ Good hydrophilicity◎ Excellent dispersibility

◎ 100% safety in use, FDA&ISEGA approved |

Food packag3e, Wallpapers, Airlaid paper, Nonwoven (spunlace with woodpulp) and oil exploration |

| PLA Fiber for Fiberfill | Linear: 3D / 5D / 6D / 7D / 10D / 12D / 15D / 25DLength: 51mm / 64mm / 76mm

Type: Siliconized / Non-siliconized / Solid&hollow |

◎ UV resistant◎ Natural wicking performance

◎ Outstanding filling power and resilience ◎ Low flammability and smoke generation ◎ Superior strength retention and discoloration resistance |

Homeware items, Pillow, Cushion, Duvet, Blanket, Mattress pad, Toy |

| Dope Dyed PLA Fiber | Linear: 6D / 7DLength: 64mm / 76mm

Color: Coffee, Green, Blue etc. |

◎ 100% Biodegradable◎ 100%Compostable | Needle punch nonwoven for horticultural weed control |

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for Rapid Delivery for Luggage Net - Biodegradable Biomass & compostable Polylactic acid (PLA) Yarn Fiber Natural Corn Fiber Staple Short Cut Fiber – AOPOLY , The product will supply to all over the world, such as: Nicaragua, Argentina, Ukraine, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!