OEM Factory for Dyneema Fiber - UHMWPE HMPE HPPE Dyneema Bulletproof Ballistic Cooling Staple Fiber 10D/20D/30D/50D/75D/100D/200D/350D/400D/1000D UD Fabric Sheet – AOPOLY

OEM Factory for Dyneema Fiber - UHMWPE HMPE HPPE Dyneema Bulletproof Ballistic Cooling Staple Fiber 10D/20D/30D/50D/75D/100D/200D/350D/400D/1000D UD Fabric Sheet – AOPOLY Detail:

Main Properties

◎ Lower density than water

◎ Extremely high ratio of weight-strength and weight-modulus

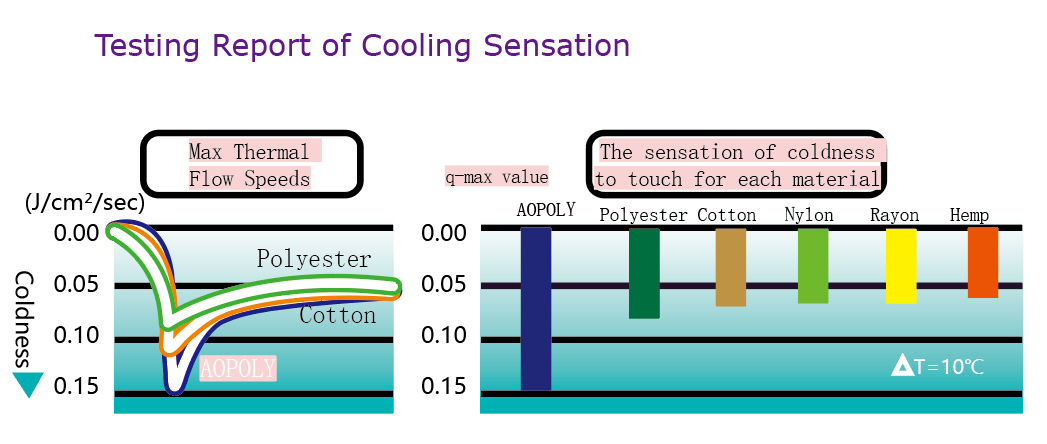

◎ At least double cooling sensation of other raw materials

◎ Excellent resistance with salty, acid, alkali and other most chemicals

◎ Resistant to stretching and bending fatigue, features a long flexibility lifetime

◎ Low elongation ratio at break, high breaking strength, outstanding cut resistance

◎ Good UV, neutron and γ-ray resistance, low dielectric constant, high electromagnetic wave transmittance

◎ Excellent impact resistance, high impact absorption capacity that is nearly 2 times greater than aramid, high abrasion resistance and low friction coefficient

Main Applications

Bulletproof Armor: bulletproof armor, ballistic helmet, bomb suppression blanket, ballistic plate, etc.

Oceaneering: drilling platform, anchor cable, towrope, mooring rope, terminal hoisting rope, etc.

Industrial Applications: cut-resistant gloves, hoisting rope, wind power cable, etc.

Aerospace Engineering: aircraft wing tip component, spacecraft component, buoy of aircraft, aviation cage, spacecraft component, etc.

Marine Fisheries: commercial fishing net, marine aquaculture net, salvage rope, towing rope, sailing rope, etc.

Outdoor Sports: climbing rope, parachute rope, sailing rope, kite line, fishing line, helmet, sail round plate, ultra-low-weight aircraft parts, etc.

Biological Material: denture base material, graft and plastic sutures, etc.

Industrial fields: pressure container, conveyor belt, filtration material, automobile cushion plate, etc.

Construction: wall, diaphragm structure, reinforced cement composite material, etc.

Parameters

Performance comparison between UHMWPE / HMPE fiber and other fibers

| Fiber Type | Steel fiber | Glass fiber | Carbon fiber | Aramid Fiber | UHMWPE fiber |

| Density (g/cm3) | 7.8 | 2.6 | 1.97 | 1.45 | 0.97 |

| Melting Point (oC) | 1150~1500 | 500~2000 | 500~560 | 135~145 | |

| Elongation (%) | 1.1-1.4 | 4.8 | 0.5~2 | 2.4~4.4 | 3.5~3.7 |

| Modulus (Gpa) | 50 | 72 | 230~400 | 60~120 | 70~132 |

| Strength (g/d) | 2.5~2.8 | 15 | 22~30 | 22~26 | 32~40 |

Specification of UHMWPE Filament Yarn

| Item No | Linear density | Tensil strength | Modulus | Elongation at break | |

| (Denier) | (dtex) | (cN/dtex) | (cN/dtex) | (%) | |

| AP-HMP-10 | 10D | 11 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-15 | 15D | 17 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-20 | 20D | 22 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-25 | 25D | 28 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-30 | 30D | 33 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-40 | 40D | 44 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-50 | 50D | 55 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-75 | 75D | 83 | ≥38 | ≥1400 | ≤3.5 |

| AP-HMP-100 | 100D | 111 | ≥35 | ≥1350 | ≤3.0 |

| AP-HMP-125 | 125D | 139 | ≥35 | ≥1350 | ≤3.0 |

| AP-HMP-150 | 150D | 165 | ≥34 | ≥1300 | ≤3.0 |

| AP-HMP-175 | 175D | 193 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-200 | 200D | 222 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-225 | 225D | 248 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-250 | 250D | 275 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-300 | 300D | 333 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-350 | 350D | 389 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-400 | 400D | 444 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-500 | 500D | 555 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-600 | 600D | 667 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-700 | 700D | 777 | ≥30 | ≥1100 | ≤3.5 |

| AP-HMP-800 | 800D | 889 | ≥34 | ≥1200 | ≤3.5 |

| AP-HMP-1200 | 1200D | 1333 | ≥34 | ≥1200 | ≤3.5 |

| AP-HMP-1600 | 1600D | 1778 | ≥34 | ≥1200 | ≤3.5 |

More UHMWPE / HMPE fiber Products

| Type | Size | Advantage | Application |

| Staple | 1.21dtex*38mm 1.21dtex*51mm 1.91dtex*38mm 1.91dtex*51mm |

Soft hand-feel, Good spinnability | Cool fabric, Apparel fabric, High strength sewing thread and industry fabric |

| Nets | Mesh Depth: Max 1000D | High strength with lower weight | Fishery, Farm fishing acquaculture net |

| Covered Yarn | With glass fiber, Steel wire, | Soft hand-feel, Cutting resistance | Cutting resistance gloves, Sports fabric |

| Spinning Yarn | With glass fiber, Steel wire | Soft hand-feel, Anti-cut, Anti-stab | Composite materials |

| UD Fabric | I, IIA, II, IIIA, III, IV | Soft texture, Good protective performance | Labor and armor protection |

| Woven & Knitted Fabric | Produced by customization | High strength, Cool feeling, Anti-cut, Anti-stab, Abrasion resistance | Sports, Industry, Hometextile |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for OEM Factory for Dyneema Fiber - UHMWPE HMPE HPPE Dyneema Bulletproof Ballistic Cooling Staple Fiber 10D/20D/30D/50D/75D/100D/200D/350D/400D/1000D UD Fabric Sheet – AOPOLY , The product will supply to all over the world, such as: Moscow, Lithuania, Paris, Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.