UHMWPE HMPE HPPE Dyneema Serat Pokok Pendingin Balistik Anti Peluru 10D/20D/30D/50D/75D/100D/200D/350D/400D/1000D Lembar Kain UD

Properties utama

◎ Kapadhetan luwih murah tinimbang banyu

◎ Rasio bobot-kekuatan lan modulus bobot sing dhuwur banget

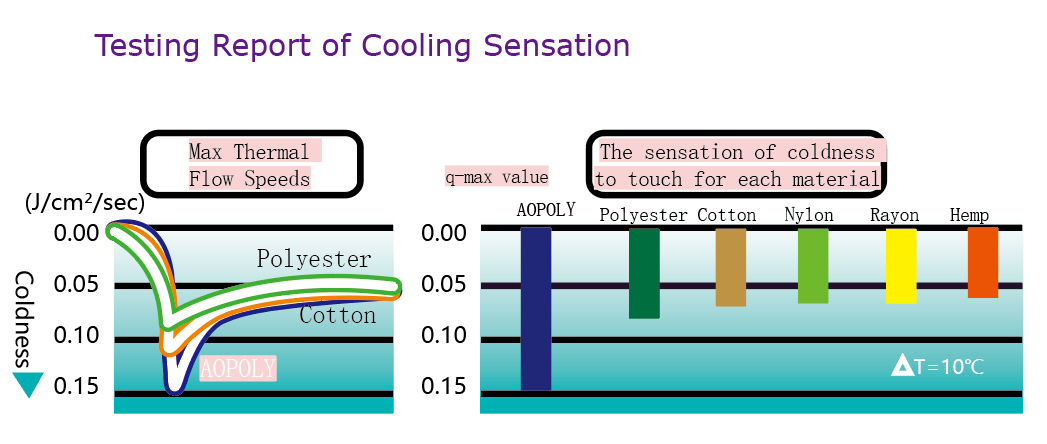

◎ Sensasi pendinginan paling ora kaping pindho saka bahan mentah liyane

◎ Resistensi banget karo asin, asam, alkali lan bahan kimia liyane

◎ Tahan kanggo mulet lan mlengkung lemes, fitur umur keluwesan dawa

◎ rasio elongation Low ing break, dhuwur bejat kekuatan, pinunjul resistance Cut

◎ Tahan UV, neutron lan sinar γ sing apik, konstanta dielektrik sing sithik, transmisi gelombang elektromagnetik sing dhuwur

◎ Resistance impact sing apik, kapasitas panyerepan impact dhuwur sing meh 2 kali luwih gedhe tinimbang aramid, resistance abrasion dhuwur lan koefisien gesekan sing kurang

Aplikasi Utama

Armor anti peluru: armor anti peluru, helm balistik, kemul penindasan bom, piring balistik, lsp.

Oceaneering: platform pengeboran, kabel jangkar, towrope, mooring tali, terminal hoisting tali, etc.

Aplikasi Industri: sarung tangan tahan potong, tali angkat, kabel tenaga angin, lsp.

Teknik Aerospace: komponen tip sayap pesawat, komponen pesawat ruang angkasa, pelampung pesawat, kandang penerbangan, komponen pesawat ruang angkasa, lsp.

Perikanan Laut: jaring ikan komersial, jaring akuakultur laut, tali penyelamat, tali penarik, tali layar, lsp.

Olahraga Luar Ruangan: tali panjat tebing, tali parasut, tali pelayaran, garis layang-layang, garis pancing, helem, piring bunder layar, bagean pesawat sing kurang bobot, lsp.

Bahan biologis: bahan dasar gigi tiruan, jahitan lan jahitan plastik, lsp.

Bidang industri: wadhah tekanan, sabuk konveyor, bahan filtrasi, piring bantal mobil, lsp.

Konstruksi: tembok, struktur diafragma, bahan komposit semen sing dikuatake, lsp.

Paramèter

Perbandingan kinerja antarane serat UHMWPE / HMPE lan serat liyane

| Jinis Serat | Serat baja | serat kaca | serat karbon | Serat Aramid Kab | serat UHMWPE |

| Kapadhetan (g/cm3) | 7.8 | 2.6 | 1.97 | 1.45 | 0.97 |

| Titik lebur (oC) | 1150~1500 | 500~2000 | 500~560 | 135~145 | |

| Elongation (%) | 1.1-1.4 | 4.8 | 0.5~2 | 2.4~4.4 | 3.5~3.7 |

| Modulus (Gpa) | 50 | 72 | 230~400 | 60~120 | 70~132 |

| Kekuwatan (g/d) | 2.5~2.8 | 15 | 22~30 | 22~26 | 32~40 |

Spesifikasi Benang Filamen UHMWPE

| Item No | Kapadhetan linear | Kekuwatan tensil | Modulus | Elongation ing break | |

| (Denier) | (dtex) | (cN/dtex) | (cN/dtex) | (%) | |

| AP-HMP-10 | 10D | 11 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-15 | 15D | 17 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-20 | 20D | 22 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-25 | 25D | 28 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-30 | 30D | 33 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-40 | 40D | 44 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-50 | 50D | 55 | ≥40 | ≥1500 | ≤3.5 |

| AP-HMP-75 | 75D | 83 | ≥38 | ≥1400 | ≤3.5 |

| AP-HMP-100 | 100D | 111 | ≥35 | ≥1350 | ≤3.0 |

| AP-HMP-125 | 125D | 139 | ≥35 | ≥1350 | ≤3.0 |

| AP-HMP-150 | 150D | 165 | ≥34 | ≥1300 | ≤3.0 |

| AP-HMP-175 | 175D | 193 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-200 | 200D | 222 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-225 | 225D | 248 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-250 | 250D | 275 | ≥33 | ≥1250 | ≤3.0 |

| AP-HMP-300 | 300D | 333 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-350 | 350D | 389 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-400 | 400D | 444 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-500 | 500D | 555 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-600 | 600D | 667 | ≥32 | ≥1200 | ≤3.0 |

| AP-HMP-700 | 700D | 777 | ≥30 | ≥1100 | ≤3.5 |

| AP-HMP-800 | 800D | 889 | ≥34 | ≥1200 | ≤3.5 |

| AP-HMP-1200 | 1200D | 1333 | ≥34 | ≥1200 | ≤3.5 |

| AP-HMP-1600 | 1600D | 1778 | ≥34 | ≥1200 | ≤3.5 |

Produk serat UHMWPE / HMPE liyane

| Jinis | Ukuran | Kaluwihan | Aplikasi |

| pokok | 1.21dtex * 38mm 1.21dtex * 51mm 1.91dtex * 38mm 1.91dtex * 51mm | Rasa tangan alus, Spinnability apik | Kain kelangan, Kain rasukan, benang jahitan kekuatan dhuwur lan kain industri |

| Jaring | Ambane Mesh: Max 1000D | Kekuwatan dhuwur kanthi bobot sing luwih murah | Perikanan, Jaring Perikanan Perikanan |

| Benang sing ditutupi | Kanthi serat kaca, kawat baja, | Soft tangan-rasa, Cut resistance | Sarung tangan tahan potong, Kain olahraga |

| Benang Spinning | Kanthi serat kaca, kawat baja | Rasa tangan alus, Anti-cut, Anti-stab | Bahan komposit |

| Kain UD | I, IIA, II, IIIA, III, IV | Tekstur alus, kinerja protèktif sing apik | Buruh lan pangayoman waja |

| Kain Tenun & Rajut | Diprodhuksi kanthi kustomisasi | Kekuwatan dhuwur, Rasa kelangan, Anti-cut, Anti-stab, tahan abrasi | Olahraga, Industri, Hometextile |