Biodegradable Biomass & Compostable Polylactic acid (PLA) Xov Paj Fiber Natural Pob kws Fiber Staple Short Cut Fiber

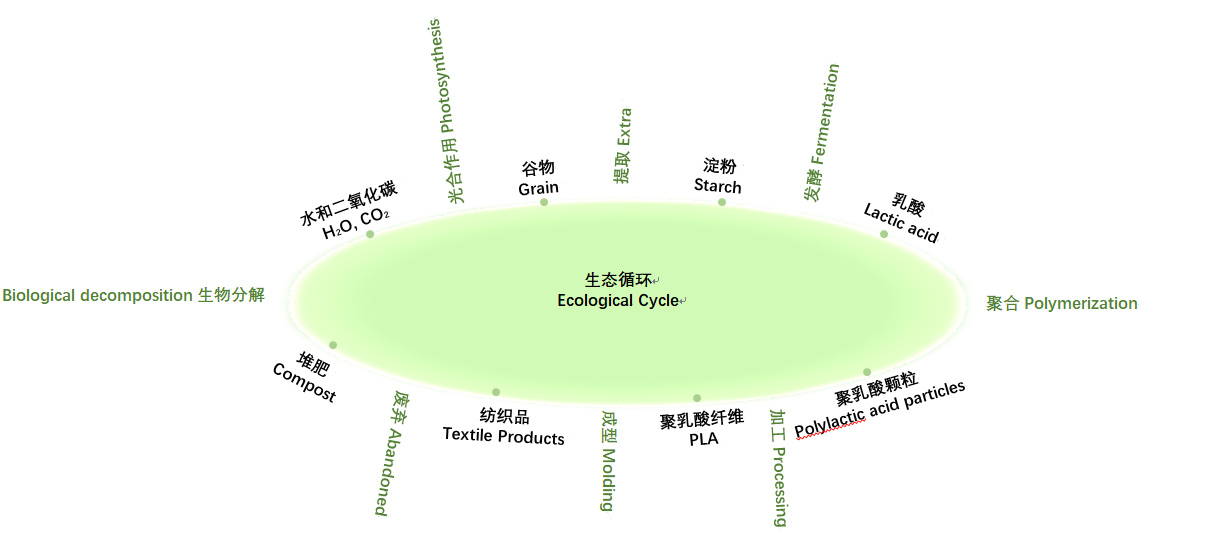

Polylactic acid fiber (PLA) tseem hu ua polylactide fiber yog ib hom tshiab ntawm biodegradable biomass fiber uas siv cov khoom siv txuas ntxiv mus ntxiv (xws li pob kws, nplej, thiab tapioca starch) ua raw cov ntaub ntawv kom tau cov piam thaj los ntawm saccharification.Qee hom kab mob yog fermented los tsim high-purity lactic acid, thiab polylactic acid nrog ib tug tej yam hnyav molecular yog synthesized los ntawm cov tshuaj synthesis txoj kev, ces polymerized thiab spun los ua tshiab fibers uas yog tej yam ntuj tso khoom nyob rau hauv cov kab mob (xws li tib neeg lub cev).PLA fiber ntau muaj biocompatibility zoo thiab bioabsorbability nrog rau zoo biodegradability, bacteriostasis, nplaim retardancy, warmth retention, noo noo nqus thiab breathability.Polylactic acid fiber (PLA) yog tsim los ntawm cov hmoov txhuv nplej siab nrog lactic acid ua raw khoom thiab cov txheej txheem ntau lawm yog tsis muaj kuab paug.Cov khoom pov tseg tom qab siv tau tuaj yeem degraded tag nrho rau hauv carbon dioxide thiab dej los ntawm cov kab mob hauv cov av thiab dej, thiab yuav tsis ua phem rau ib puag ncig.Nyob rau hauv tshav ntuj thiab photosynthesis, cov nroj tsuag tuaj yeem tsim cov pa roj carbon dioxide thiab dej hauv huab cua rau hauv cov hmoov txhuv nplej siab uas tuaj yeem rov ua dua tshiab.Qhov no muaj txiaj ntsig zoo rau kev tiv thaiv ib puag ncig thiab tau lees paub tias yog cov khoom siv ntsuab ntsuab thiab cov khoom siv zoo ib puag ncig.

Antibacterial mechanism: Cov roj ntsha uas tsis muaj polymerization fatty acid hauv PLA fiber tuaj yeem rhuav tshem cov phab ntsa ntawm tes / membrane.Cov tshuaj acidic tso tawm los ntawm qis-polymerization fatty acid chain rhuav tshem cov kua qaub-puag hauv lub cev ntawm lub cev, ua rau cov kua dej nkag mus rau hauv lub cev, uas ua rau muaj kev sib txuas ntawm cov saw hlau uas nws thiaj li rhuav tshem qhov chaw nyob ntawm cov kab mob, Kev tuag ntawm cov kab mob phem.

Main Khoom

◎ Kev tiv thaiv ib puag ncig: PLA cov khoom faus rau hauv av lossis dej yuav decompose rau hauv CO2 thiab H2O

◎ Kev ua haujlwm zoo: zoo sib xws lub zog thiab elongation nrog polyester thiab nylon, thaum qis tshaj melting point thiab qis modulus

◎ Mos thiab du: nrog silk-zoo li mos luster thiab kov, zoo drape, tam sim no ze rau mulberry silk

◎ Zoo biocompatibility: muab los ntawm cov nroj tsuag ntuj, tsis muaj zog acidic

◎ Ntuj tawv-phooj ywg: tshwj xeeb tshaj yog haum rau kev tsis haum tshuaj, cov poj niam cev xeeb tub, me nyuam mos thiab pab pawg tshwj xeeb

◎ Rwb thaiv tsev ze-fitting: zoo resilience, siab fluffiness, sov yog 1.8 npaug ntau dua cov paj rwb zoo

◎ Bacteriostatic thiab anti-mite: textiles yuav txiav tawm 17 me me molecules xws li lactic acid thaum siv, yuam mites kom khiav, thiab bacteriostatic tus nqi ntawm cov kab mob thiab fungi yog ntau dua 98%, uas muaj zoo heev anti-mite thiab anti- cov teebmeem mite.

◎ Breathable & noo noo tshem tawm: tshwj xeeb fiber ntau microstructure coj zoo heev breathable thiab ya raws conductivity

◎ Cov nplaim hluav taws zoo heev, tiv thaiv tshav kub thiab UV tiv thaiv

Cov ntawv thov tseem ceeb

Khaub ncaws, txaj, khoom siv tu cev, ris tsho hauv qab, khoom niam thiab menyuam, thom khwm.

Tsis muaj

Kev sib piv ntawm cov khaub ncaws ua haujlwm ntawm PLA fiber ntau thiab lwm cov fibers

| Fiber hom | Polyester | Paj rwb | Silk | Xyoob Fiber | PLA |

| acteria thiab mite tsis kam | pluag | pluag | Ncaj ncees | Zoo | Zoo heev |

| Ua pa | pluag | Ncaj ncees | pluag | Zoo | Zoo heev |

| Hluav taws kub | 20 | 16 | 17 | 18 | 26-30 : kuv |

| Tus nqi PH | - | - | 7 | - | 6 ~ 6.3 |

| Degradability | Neeg pluag heev | Zoo | Zoo | Zoo | Zoo heev |

| Drapability | Ncaj ncees | pluag | Zoo | pluag | Zoo heev |

| Wrinkle kuj | Zoo | Ncaj ncees | pluag | Ncaj ncees | Zoo heev |

| Thaum tshav kub kub tuav | Ncaj ncees | Zoo | pluag | Zoo | Zoo |

| Kev ua haujlwm txias | Ncaj ncees | Zoo | pluag | Zoo | Zoo heev |

| Cov khoom nyoos | Roj av | Paj rwb | Silk | Xyoob | Lactic acid |

| Kev qias neeg | Tshuaj lom neeg | Tshuaj tua kab residue | Tsis muaj | Tshuaj rho tawm | Tsis muaj |

Kev ua tau zoo sib piv ntawm PLA fiber ntau thiab lwm cov fibers

| Fiber hom | Paj rwb | Viscose | Silk | Cov ntaub plaub | PLA | Nylon | Polyester | Acrylic |

| txheeb ze ntom ntom | 1.52 ib | 1.52 ib | 1.3-1.45 Nws | 1.32 ib | 1.27 | 1.14 | 1.38 ib | 1.8 |

| Lub zog (g / d) | 1.9-3.1 | 2.5 | 4 | 1.6 | 3.8-4.5 | 4.5 | 4-4.5 | 4 |

| Stretch (5%) | 52 | 32 | 52 | 69 | 93 | 89 | 65 | 50 |

| Melting point (℃) | - | - | - | - | 60-175 : kuv | 215 | 255 | 320 |

| Flammability | Hlawv | Hlawv | Hlawv | Hlawv (slow) | Tsawg pa luam yeeb (tawm tom qab 2 "tsis muaj hluav taws) | Medi- haus luam yeeb | Cov pa taws ntau (tawm tom qab 6 "tsis muaj hluav taws) | Medi- haus luam yeeb |

| Thaum tshav kub kub combustion (MJ / KG) | 17 | 17 | - | 21 | 19 | 31 | 25-30 | 31 |

| Oxygen Limitation Index (%) | 16-17 | 17-19 | - | 24-25 | 28 | 20-24 | 20-22 | 18 |

| UV tsis kam | Ncaj Ncees | pluag | Ncaj Ncees | Ncaj ncees | Zoo heev | pluag | Ncaj ncees | Zoo heev |

| Gloss lub kaum sab xis | 1.53 ib | 1.52 ib | 1.54 ib | 1.54 ib | 1.35-1.45 dr hab | 1.52 ib | 1.54 ib | 1.5 |

| Dej sib cuag lub kaum sab xis | - | - | - | - | 76 | 70 | 82 | - |

| Txoj kev spinning | - | Kev ntub dej | - | - | Melting spinning | Melting spinning | Melting spinning | Qhuav spinning |

Specification

| Fiber hom | Loj | Cov khoom | Daim ntawv thov |

| PLA FDY & PLA DTY | FDY: Linear: 75D ~ 300D / 36F ~ 96F DTY: Tawm: 50D ~ 200D / 24F ~ 72F | ◎ Antibacterial lawm ◎ Rov ua dua & ruaj khov ◎ 100% Biodegradable & compostable ◎ Tsawg carbon thiab tus phooj ywg nrog ib puag ncig | Khaub ncaws, Textile |

| PLA Microfiber | Linear: 0.5D ~ 0.9D Ntev: 5mm / 6mm / 12mm / 18mm / 38mm / 51mm / 64mm ~ 102mm Hom: Crimp / Uncrimp | ◎ Mos zoo ◎ Zoo noo noo bsorbency | Nonwoven, Ntawv-ua, Roj tshawb nrhiav, Apparel, Textile |

| PLA Fiber rau Spinning | Tawm: 0.5D / 0.6D / 0.8D / 0.9D / 1.2D / 1.3D / 1.5D / 2D / 3D Ntev: 36mm / 38mm / 51mm | ◎ Tsis hnov tsw ◎ Lub teeb thiab siab zoo ◎ Cov tawv nqaij affinity zoo heev ◎ Kev thauj mus los zoo ◎ Zoo heev zoo tuav thiab crease kuj | Ntshiab los yog blending spinning rau khaub ncaws thiab textile |

| PLA Staple Fiber ntau | Linear: 0.8D / 0.9D / 1.2D / 1.3D / 1.5D / 2D / 3D Ntev: 5mm / 6mm / 12mm / 18mm Qhuav los yog noo noo 15% | ◎ Zoo hydrophilicity ◎ Dispersibility zoo heev ◎ 100% kev nyab xeeb hauv kev siv, FDA & ISEGA pom zoo | Food packag3e, Wallpapers, Airlaid paper, Nonwoven (spunlace with woodpulp) thiab kev tshawb nrhiav roj |

| PLA fiber ntau rau fiber ntau | Linear: 3D / 5D / 6D / 7D / 10D / 12D / 15D / 25D Ntev: 51mm / 64mm / 76mm Hom: Siliconized / Non-siliconized / Khoom & Hollow | ◎ UV tiv taus ◎ Natural wicking kev ua tau zoo ◎ Ua kom muaj zog thiab ua haujlwm zoo ◎ Tsawg flammability thiab haus luam yeeb tiam ◎ Superior zog tuav thiab discoloration kuj | Cov khoom siv hauv tsev, hauv ncoo, Cushion, Duvet, Pam, txaj txaj, Khoom ua si |

| Dope Dyed PLA Fiber ntau | Linear: 6D / 7D Ntev: 64mm / 76mm Xim: Kas fes, Ntsuab, Xiav thiab lwm yam. | ◎ 100% Biodegradable ◎ 100% Compostable | Koob punch nonwoven rau horticultural nroj tsuag tswj |